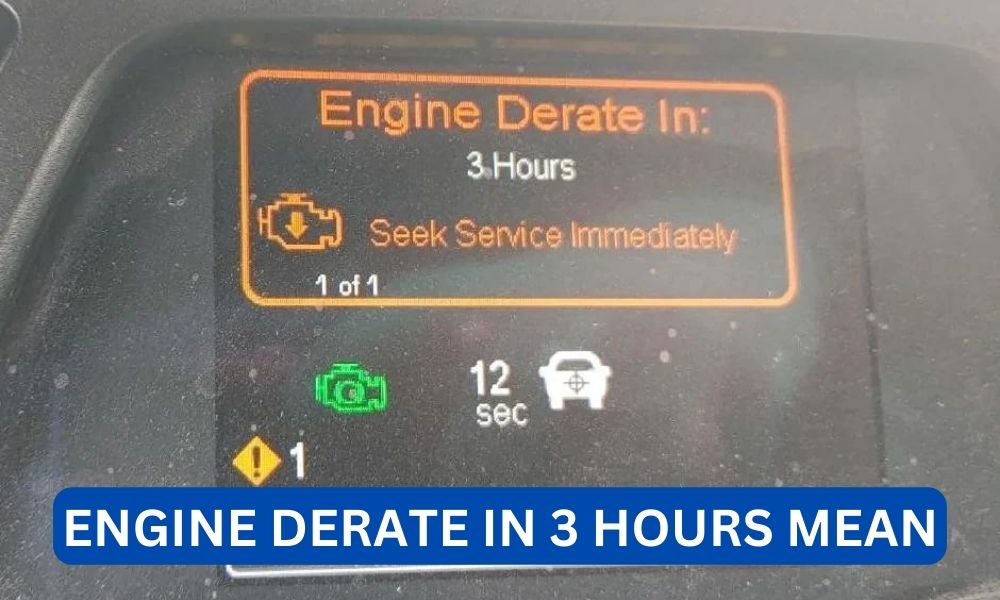

Engine derate in 3 hours is a term commonly used in the aviation industry to describe a situation where an aircraft’s engine power is reduced or limited for a specific period of time. This derating is usually implemented as a precautionary measure to ensure the safe operation of the aircraft and its engines. In this article, we will explore the concept of engine derate in 3 hours, its significance, and the reasons behind its implementation.

Contents

The Basics of Engine Derate

Before diving into the specifics of engine derate in 3 hours, it is essential to understand the concept of engine derating in general. Engine derating refers to the intentional reduction of an engine’s power output below its maximum rated capacity. This reduction can be achieved through various means, such as adjusting the fuel flow, limiting the maximum rotational speed, or modifying the engine control system.

Engine derating is a common practice in the aviation industry to optimize engine performance, increase fuel efficiency, and enhance engine longevity. By operating an engine at a lower power output, it experiences less stress and wear, resulting in reduced maintenance requirements and extended service life.

The Significance of Engine Derate in 3 Hours

Engine derate in 3 hours specifically refers to a derating condition that is limited to a three-hour duration. This time limit is imposed to ensure that the engine operates within safe limits and does not exceed its design limitations. After the three-hour period, the engine can resume normal operation or may require further derating, depending on the specific circumstances.

Read:What is eec relay?The significance of engine derate in 3 hours lies in its role in preventing engine damage or failure due to prolonged operation at high power levels. Engines are designed to withstand a certain amount of stress and heat, and exceeding these limits can lead to catastrophic consequences, including engine failure, in-flight emergencies, or even accidents.

By implementing a derating condition for a limited time, aircraft operators can strike a balance between performance and safety. This allows them to utilize the engine’s full potential when necessary while ensuring that it operates within safe limits and avoids any potential risks associated with prolonged high-power operation.

Reasons for Engine Derate in 3 Hours

There are several reasons why engine derate in 3 hours may be implemented. Let’s explore some of the most common scenarios where this derating condition is applied:

- High Ambient Temperatures: In hot weather conditions, the air density decreases, affecting the engine’s performance. To compensate for this, engine derate in 3 hours may be used to reduce the power output and prevent the engine from overheating.

- High Altitude Operations: At high altitudes, the air pressure decreases, resulting in reduced engine performance. Engine derate in 3 hours can be employed to ensure that the engine operates within safe limits and maintains adequate power output.

- Engine Maintenance or Inspection: During scheduled maintenance or inspections, engine derate in 3 hours may be implemented to limit the stress on the engine components and reduce the risk of damage during the procedure.

- Temporary Engine Issues: If an engine experiences a temporary issue or malfunction, such as a sensor failure or abnormal vibrations, engine derate in 3 hours can be used as a precautionary measure until the issue is resolved or further investigation is conducted.

Case Study: Engine Derate in 3 Hours in Commercial Aviation

To illustrate the practical application of engine derate in 3 hours, let’s consider a case study in the commercial aviation sector. Imagine an airline operating a fleet of long-haul aircraft that frequently fly routes with high ambient temperatures.

Read:What are the benefits of leasing a car?During the summer months, when temperatures soar, the airline implements engine derate in 3 hours for its aircraft departing from airports located in hot regions. By reducing the engine power output, the airline ensures that the engines operate within safe temperature limits and avoids the risk of overheating or engine damage.

This derating condition allows the airline to continue operating its flights without significant disruptions while maintaining the safety and reliability of its aircraft. After the three-hour derating period, the engines can resume normal operation, provided that the ambient temperature has decreased to a safe level.

The Benefits and Drawbacks of Engine Derate in 3 Hours

Engine derate in 3 hours offers several benefits to aircraft operators, including:

- Enhanced safety by preventing engine damage or failure due to prolonged high-power operation.

- Extended engine service life and reduced maintenance requirements.

- Optimized engine performance and fuel efficiency.

- Flexibility in adapting to varying operating conditions, such as high ambient temperatures or high-altitude operations.

However, there are also some drawbacks associated with engine derate in 3 hours:

- Reduced aircraft performance during the derating period, which may result in longer flight durations or limited payload capacity.

- Potential operational complexities, such as coordinating derating conditions with air traffic control or adjusting flight schedules to accommodate derating requirements.

- Additional training and procedures for flight crews to ensure proper implementation and understanding of engine derate in 3 hours.

Summary

Engine derate in 3 hours is a crucial concept in the aviation industry that involves intentionally reducing an aircraft engine’s power output for a limited duration. This derating condition is implemented to ensure safe engine operation, prevent damage or failure, and optimize engine performance and longevity.

Read:What is a fisting kit?Engine derate in 3 hours is commonly used in scenarios such as high ambient temperatures, high-altitude operations, engine maintenance or inspection, and temporary engine issues. While it offers benefits such as enhanced safety and extended engine service life, it also comes with drawbacks such as reduced aircraft performance and operational complexities.

Understanding engine derate in 3 hours is essential for aviation professionals, as it allows them to make informed decisions regarding engine operation and maintenance, ensuring the safety and efficiency of aircraft operations.