Batch size refers to the number of units produced or processed at a given time in a production or manufacturing process. In other words, it is the quantity of goods or services that are produced or processed in a single batch. Reducing batch size is a concept that has gained significant attention in recent years, especially in the manufacturing industry. It involves breaking down the production process into smaller batches, resulting in a lower number of units produced or processed at a time. This article will explore the major benefit of reducing batch size and how it can positively impact businesses and industries.

Contents

Understanding Batch Size and Its Impact

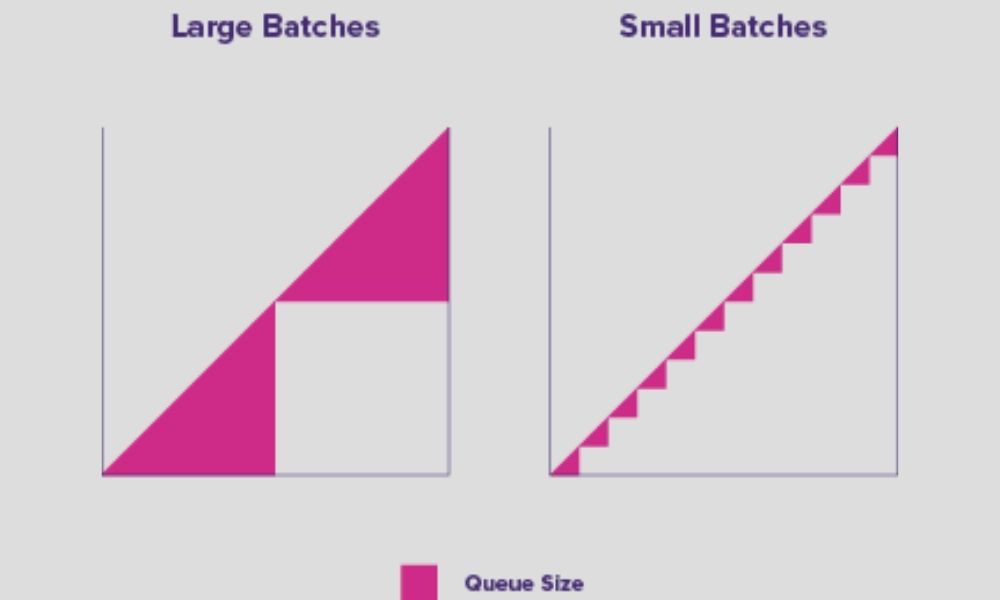

Batch size has a significant impact on the efficiency and productivity of a production process. A larger batch size means that more units are produced or processed at a time, resulting in longer lead times and higher inventory levels. On the other hand, a smaller batch size means that fewer units are produced or processed at a time, resulting in shorter lead times and lower inventory levels. The decision to reduce batch size is often driven by the need to improve efficiency and reduce costs. However, there are other major benefits of reducing batch size that businesses and industries can reap.

Read:when Do you start applying for scholarships?The Major Benefit of Reducing Batch Size: Improved Flexibility

One of the major benefits of reducing batch size is improved flexibility. In today’s fast-paced and ever-changing business environment, flexibility is crucial for businesses to remain competitive. By reducing batch size, businesses can quickly adapt to changes in demand, market trends, and customer preferences. Smaller batch sizes allow for more frequent production runs, making it easier for businesses to adjust their production levels to meet changing market demands. This flexibility also enables businesses to introduce new products or make changes to existing ones more quickly, giving them a competitive edge in the market.

For example, Toyota, a leading automotive manufacturer, has implemented a production system known as “Just-in-Time” (JIT), which involves reducing batch sizes to improve flexibility. By implementing this system, Toyota has been able to quickly respond to changes in customer demand and market trends, resulting in increased sales and customer satisfaction. The company’s ability to produce smaller batches of different models has also allowed them to introduce new models more frequently, keeping them ahead of their competitors.

Reduced Lead Times and Inventory Levels

Another major benefit of reducing batch size is the reduction in lead times and inventory levels. As mentioned earlier, larger batch sizes result in longer lead times, which can be a significant disadvantage for businesses. Longer lead times mean that customers have to wait longer to receive their orders, which can lead to dissatisfaction and loss of business. Additionally, larger batch sizes also result in higher inventory levels, which tie up a significant amount of capital and increase storage costs.

Read:Can you get a wrestling scholarship?By reducing batch size, businesses can significantly reduce lead times and inventory levels. Smaller batch sizes mean that production runs are completed more quickly, resulting in shorter lead times. This allows businesses to fulfill customer orders more quickly, improving customer satisfaction and retention. Smaller batch sizes also mean that businesses can produce only what is needed, reducing excess inventory and freeing up capital for other investments.

Improved Quality Control

Reducing batch size can also lead to improved quality control. In larger batch sizes, it is more challenging to identify and rectify defects or errors, as they are spread out over a larger number of units. This can result in a higher number of defective units being produced, leading to increased costs and customer dissatisfaction. By reducing batch size, businesses can focus on producing smaller batches of high-quality products, making it easier to identify and address any issues that may arise.

For example, the food and beverage industry has seen significant improvements in quality control by reducing batch size. By producing smaller batches, businesses can closely monitor the production process and ensure that each batch meets the required quality standards. This has resulted in a decrease in the number of product recalls and an increase in customer satisfaction.

Read:Does harvard university give athletic scholarships?Cost Savings:

Reducing batch size can also lead to cost savings for businesses. While it may seem counterintuitive that producing smaller batches can result in cost savings, there are several ways in which this can be achieved. Firstly, by reducing lead times and inventory levels, businesses can save on storage costs and reduce the risk of excess inventory. Secondly, by improving quality control, businesses can reduce the costs associated with defective products, such as recalls and customer returns. Lastly, by improving flexibility, businesses can quickly adapt to changes in demand, reducing the risk of overproduction and wastage.

For example, a study conducted by the Lean Enterprise Institute found that reducing batch size can lead to a 50% reduction in inventory levels and a 90% reduction in lead times. This resulted in a 50% reduction in costs for the companies that implemented this strategy.

Challenges of Reducing Batch Size

While there are significant benefits to reducing batch size, it is not without its challenges. One of the main challenges is the initial investment required to implement this strategy. Reducing batch size often involves changes to the production process, which can be costly and time-consuming. Additionally, businesses may also face resistance from employees who are used to working with larger batch sizes and may be resistant to change.

Another challenge is the need for efficient and effective communication and coordination between different departments and suppliers. Smaller batch sizes mean that production runs are more frequent, and any delays or issues in the supply chain can have a significant impact on the production process. Therefore, it is crucial for businesses to have a well-coordinated supply chain to ensure the success of this strategy.

Conclusion:

In conclusion, reducing batch size has numerous benefits for businesses and industries. It can improve flexibility, reduce lead times and inventory levels, improve quality control, and result in cost savings. However, it is essential to note that reducing batch size is not a one-size-fits-all solution and may not be suitable for all businesses. It is crucial for businesses to carefully consider their production processes and the potential challenges before implementing this strategy. With proper planning and implementation, reducing batch size can be a powerful tool for businesses to improve efficiency, productivity, and competitiveness in today’s dynamic business environment.